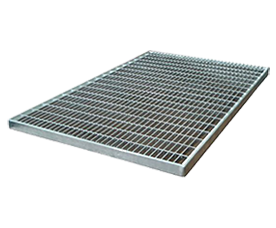

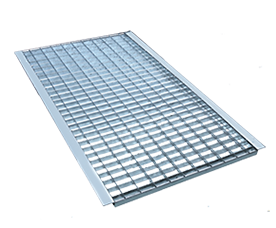

Pressure locked steel grating

Flooring made of pressed steel gratings is a versatile building material that has a high load-bearing capacity and low weight. This feature is based on the cellular structure of the grating, and that's why pressure locked grating is popular for the construction of metal structures for various purposes.

Request for grating

Connect with manager

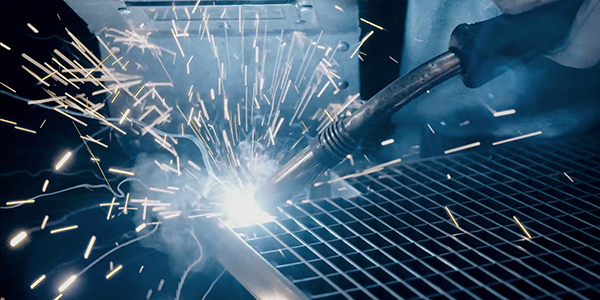

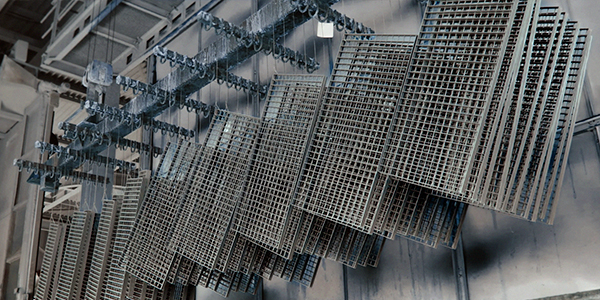

Production of pressed grating

Pressed grating produced in Ukraine and comply with DIN 24537-1 standard, and the technical parameters of finished products comply with the RAL GZ-638 standard. During the manufacturing process, strips with a smaller cross-section pressed into the bearing strips under high pressure. Hot-dip galvanizing is used to protect the finished gratings from corrosion.

You can order a full range of services: design, production and installation of metal structures for various tasks. We specialize in the development of non-standard cases.

Our Clients

Rational solution for shelving

Press locked grating is used in almost all areas of construction as the main element. Pressed flooring is used in the construction of office and shopping centres, flights of stairs, arrangement of floors in warehouses, walkways for pedestrians, platforms in workshops of industrial enterprises, and so on.

Pressure locked bar grating features

The structure of the pressed flooring consists of steel strips of the following types:

- bearing;

- connecting;

- framing.

The first two types of metal strips are equipped with special grooves for bonding elements under high pressure. Framing strips are fixed along the perimeter of the workpiece by welding. The main function is to provide aesthetics and protect the base of the structure from mechanical damage. To increase corrosion resistance, the gratings are galvanized.

For installation framing stripes to the frame, used a fastener called "butterfly". It is a curved bracket that has a bolt, baseplate, or hook. This mount is one of the most durable and comes with gratings.

Forstor offers modern and efficient business solutions. You can choose solutions for equipping warehouses, logistics centres and so on. There are no products on sale with the required dimensions or bearing capacity? Not a problem, we will make the solution you need, according to the characteristics of the room, working conditions and personal preferences.

You can buy products of the following types:

- pressed galvanized flooring of various sizes;

- shelf grating of various types;

- grating flooring for car washes.

If necessary, fragments of the flooring can be replaced without loss of performance. Hot-dip galvanized coating provides high corrosion resistance.

.jpg)

.jpg)

.jpg)

.png)