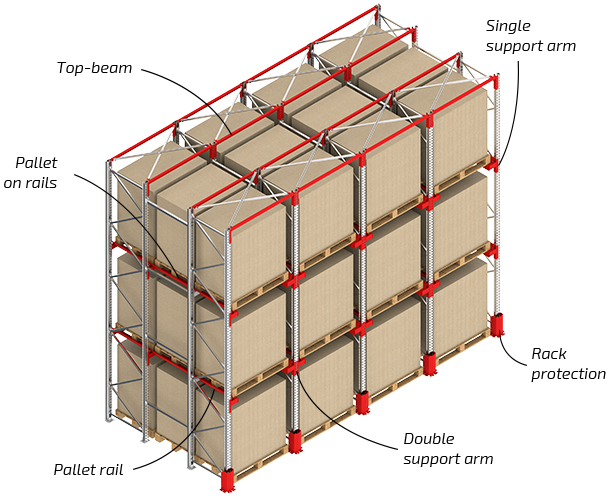

How does the drive in pallet racking system work

Pallets are located in channels on special guide rails, fixed with holders on the racks of the rack. The stuffed rack allows you to place the goods, driving the loader or stacker directly deep into the channel. Depending on the configuration of the warehouse, the features of the stored cargo and the turnover of goods, stuffed racks can be served in two different ways:

- The most common variant — LIFO principle (last arrived — first left). For one type of product, a separate corridor or several adjacent corridors is allocated. At the same time, loading and unloading operations are carried out only on the front side of the rack system.

- For quick cargo handling " walk-through " layout, with it the loading and unloading areas are separated directly by the rack. Walk-through racks work on the principle of FIFO (first in — first out).

We develop effective solutions for any premises

Using the example of this project, you can make sure that our engineers develop solutions based not on standard and template techniques, but based on the conditions and requirements of the client.

This project is notable for the fact that in a non-standard room we placed 4 blocks of drive through pallet racking in such a way as to ensure maximum storage density. At the same time, quite large corridors for the movement of equipment were preserved.

Read more

An integrated approach to solving the problem

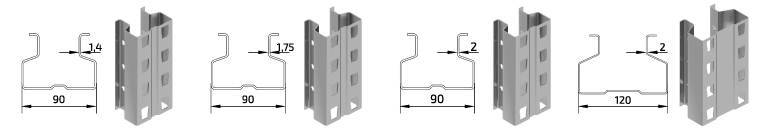

The Forstor Industry plant designs and manufactures all types of racks for pallets, offers delivery and installation in Ukraine. Since stuffed shelving is a rather complex type of shelving system, we recommend that you contact our managers to clarify all the details and nuances. They will provide you with the most detailed information about the production stages, the grades of steel used and other technical data. And our engineers will calculate the depth drive in racking system specifically for your case.

For all questions, contact the Forstor sales department. Call the indicated phone numbers or ask your question online — write to the chat, our specialist will answer you within a minute. On this page you will find all contact information: telephones, feedback form, address and map.

.png)