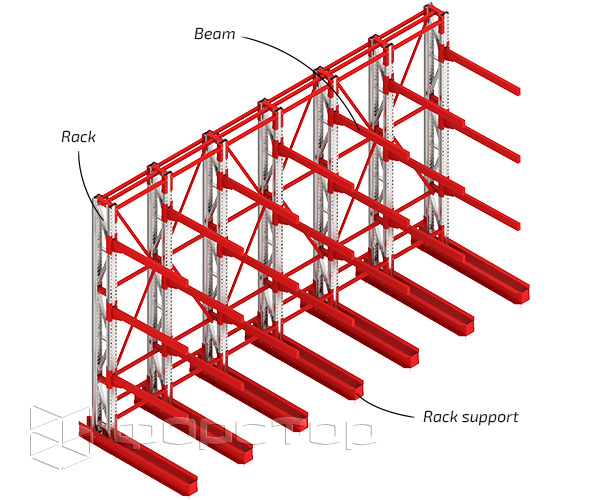

One-sided cantilever racks are most often used as wall racks. They have high static strength, stability and load capacity — an excellent solution for storing heavy long products, such as pipes, lumber, metal parts.

Storage and handling of goods is carried out from only one side of the rack — the front side. Cantilever one-sided racking is widely used in metal depots, construction stores and warehouses.

Design features

One-sided cantilever racks have a simple design: vertical posts of C-shaped profile are bolted to the base. A beam is mounted on the rack at the required height — perforations allow to adjust this height. To make the rack more stable, the stands are connected by inclined beams. The beam can be additionally equipped with roll stoppers, which is important when storing pipes.

The base of the rack is made of hot-rolled IPN profile. To make the single-sided cantilever racks as stable as possible, during their installation, the supports are fixed to the floor with anchor bolts. For greater stability, the racks can be additionally fixed to the wall.

High resistance to corrosion

Racks and consoles can be painted or galvanized, which ensures high resistance to corrosion.

Forstor operates throughout Ukraine and Europe. We specialize in complex integrated projects: we develop, manufacture, deliver to the customer's site and install racking systems of any complexity.

.png)