Gravity Pallet Racking: Features

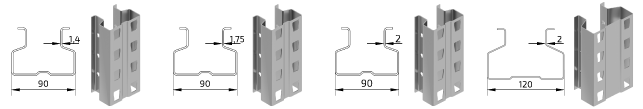

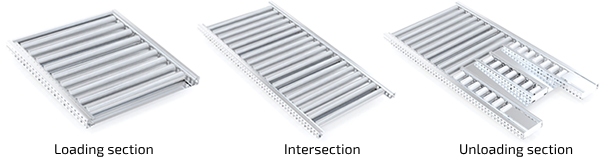

Roller racking systems allow for self-movement of goods under the influence of gravity. Palletized items move towards the unloading area along roller tracks. On average, the incline of the guides is 4–5 angle degree. Roller guides are equipped with a system of stoppers and braking mechanisms. The rack beams are made of two C-shaped metal profiles that are welded together. This doubles the load-bearing capacity of the beam. The beam is fixed to the upright using a 5-tooth bracket, ensuring high structural strength.

Forstor Company manufactures gravity pallet racking. Storage of goods in such systems is based on the "First In First Out" (FIFO) principle. The unloading sequence matches the loading order. This type of racking system is ideal for goods with a limited shelf life.

We offer gravity racking systems of various configurations directly from the manufacturer. In Ukraine, mobile racking systems are not yet very popular due to their relatively high cost. However, practice shows that such equipment pays for itself on average in 1.5-2 years. Along with these, we can also recommend drive-in pallet racking, which is suitable for storing pallets of approximately the same dimensions.

If you require any further assistance, call our managers or use the feedback form (activated by the "Ask us a question" button). You can also find → a full list of contacts and a map to our head office on this page.

.png)