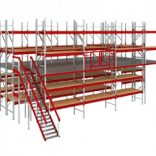

Heavy duty mezzanine case study for auto parts warehouse

Total storage area on the mezzanine 600 m²

Construction height 7 m

Racking system for 135 pallets

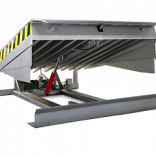

Dock leveller 2000x2500 mm

One of our regular customers – the largest importer of trucks, buses and special equipment – contacted us with the task of designing and equipping a warehouse for auto parts storage. According to the features of the storage of auto parts, our engineers have developed a combined storage system: a three-tier mezzanine and pallet racks for three levels. To optimize loading operations, we manufactured and installed a dock leveller in the warehouse dock.

On the first level the mezzanine has an arched driveway for free forklift transition. On the second and third floors, there are 4 loading platforms with gates – two on each side of the multi level mezzanine for parts storage.

Total building area – 130 m²

Achieved useful storage area of 600 m²

Arched driveway on the first floor

Allows the forklift loader to drive to any part of the warehouse

Shelving made of chipboard sheets

Load capacity up to 150 kg/m²

Floors made of grating

Load capacity up to 500 kg/m²

Gate on both sides of the mezzanine

4 loading platforms on the second and third floors

Forstor dock leveller

Platform dimensions – 2000x2500 mm

Platform working stroke – 310 mm

Dynamic load capacity of 6000 kg

Rack shelf depth 1000 mm

Each shelf is equipped with a galvanized separator

Welded staircase with optimal slope

Fastening the floors to the beams

.png)