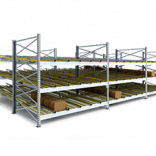

Gravity racking as main basis for a highly efficient warehouse system

Forstor's client was a well-known online cosmetics store in Ukraine, which faced the challenge of organizing efficient space in a new warehouse. The task was not just to place products on the racks, but to maximize order picking productivity and overall warehouse efficiency. We developed a comprehensive solution that includes three types of racks and a roller conveyor:

- Gravity racks Profi — for arranging an efficient order picking area.

- Master shelving — for medium-term storage of goods in the picking area.

- Pallet racking Profi — for organizing a long-term storage area for goods on pallets.

- Roller conveyor — a roller picking line with a total length of more than 30 meters.

The project is based on gravity racks: 11 sections are arranged in a "U" shape. Each section has 3 inclined roller tiers on which boxes with small-piece products are placed. As soon as the front box is empty, it is enough to simply pull it out, and the next one will " roll up" in its place.

A roller conveyor is mounted on the outer perimeter of the gravity system for quick and easy movement of baskets or boxes for order picking. This is a roller conveyor with a complex path and two rotary blocks — the total length of the line is more than 30 meters. The system works in such a way that the picker can collect any order in a single run.

Along the perimeter of the order picking area, there are 21 shelf racks where boxes are stored for further loading onto gravity racks. In a separate warehouse area, there are 40 sections of pallet racks with a total capacity of 350 pallets. This is a long-term storage area.

.png)