Optimization of lumber production

One of the leaders of the woodworking industry in Ukraine contacted us with the task of optimizing internal logistics at the production site. It was necessary to develop lifting equipment for several areas to move raw materials and finished products.

We developed a set of lifting equipment, including:

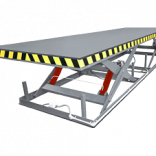

- A three-scissor lifting platform.

- Scissor unloading table.

- A cantilevered wall-mounted lift.

The most interesting equipment in the project is the three-scissor platform, which allows to move large loads between the floors of the production facility. Since lumber production is noisy, the process of lifting heavy and oversized loads should be as visible and safe as possible. For this purpose, the platform is equipped with light and noise indication and a safety fence.

The scissor lift is typical equipment for optimizing the movement of goods between the industrial and warehouse areas.

The cantilever lift is designed to quickly move small-sized products and raw materials between production floors.

.png)