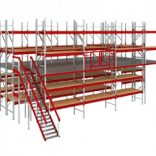

Five-storey automated mezzanine and pallet racking system

We were approached by one of the largest distributors of construction tools and materials in Ukraine with a large-scale project: to develop an efficient storage system for a new warehouse in Lviv with an area of more than 2774 m². The system had to meet the needs for long-term and medium-term storage of a wide range of goods, as well as ensure fast order processing and picking. We developed a complex warehouse system consisting of a five-story automated mezzanine and pallet-shelf racking.

The mezzanine is located on a building area of 739 m². The structure has 5 floors, which resulted in a total usable storage area of 3725 m². This means that the storage efficiency has increased by more than 4.7 times. Each floor of the mezzanine has 4 storage levels — 3 shelves + floor. The maximum load per shelf is 700 kg. The bearing capacity of the interfloor slabs is 200 kg\m², which makes it possible to use a warehouse trolley on the upper floors

Efficiency and fast order picking are important to the customer, so a lifting and conveyor system was included in the mezzanine project to automate order picking. Roller conveyors on each floor automate the order picking process: the goods collected in plastic baskets are sent to the elevator, which sends the baskets to the first floor to transfer the order for packaging. This significantly increases the productivity of logistics operations.

The mezzanine infrastructure also includes safety mechanisms, such as handrails around the perimeter of each floor and a specialized shaft with a grating fence, which guarantees the safe movement of goods.

The second component of the combined warehouse system is pallet-shelf racking, which forms a medium- and long-term storage area. The two lower levels are equipped with shelves for boxes and piece goods. The upper levels are designed for pallet storage. The total capacity of the system consists of 2789 pallet spaces and 356 shelves, with a usable area of 1057 m².

.png)