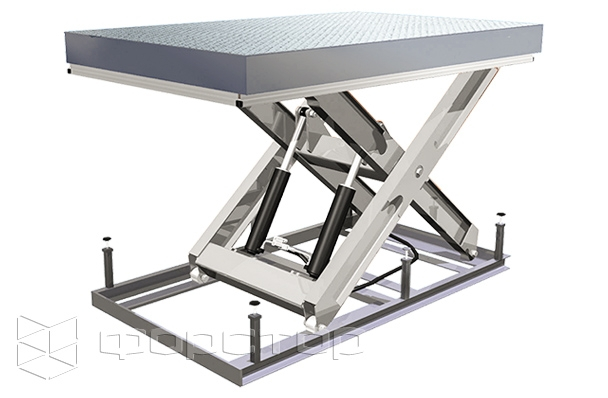

Advantages of Galvanized Lifts

-

The hot-dip galvanizing procedure provides a high level of corrosion protection.

-

The lift does not require registration and availability of authorization documentation for operation.

-

Easy to use lift control system

-

Protection of the control unit IP44 and above for operation in aggressive environments.

Technical specifications

|

Lifting platform length |

mm |

up to 6000 |

|

Lifting platform width |

mm |

up to 3000 |

|

Maximum lifting height |

mm |

5000 |

|

Maximum load capacity |

kg |

10000 |

|

Height in the folded state |

mm |

300-500 |

.png)